Frogwood® Engineered Colored Laminated Birch

Frogwood is a manufactured engineered laminated birch hardwood. Unlike plywood, Frogwood is constructed with the grain of all the individual laminations aligned along the same direction, and every layer is constructed from high-grade veneers. This ensures that when Frogwood blanks are turned, the material cuts consistently without any tearing of the material.

ALL Frogwood blanks are cut with the grain.

Frogwood laminations are dyed using water-soluble dyes. Please note that the dye contains glycol, and so should NOT be used in an unsealed finished product where it may leach into food. Every panel of the material made goes through an autoclave moisture removal process. This extends the manufacturing time, but it minimizes any shrinkage issues and eliminates the cracking problems often seen in imported laminated birch materials.

As in most laminated bonded wood products, Frogwood does contain some formaldehyde from the lamination bonding agent. Levels are kept as low as possible consistent with the delivery of a robust reliable product.

USA Made

Quality-first Products

Our dyed laminated birch hardwood blanks are manufactured in the USA and distributed from our Western New York facilities.

Frogwood® is being used in bow risers, game calls, pens, musical instruments, pool cues and many other products

This material has superior consistency and easy machinability, reducing manufacturing time & boosting your product's visual appeal

Frogwood® is an engineered laminated colored birch hardwood, similar to Webbwood™, Spectraply® & Rutland Colorwood®. It is a strong but lightweight material available in lengths up to 48", suitable for use in diverse applications including gun stocks and billiard cues.

FrogBlanks supplies Frogwood blanks cut to size, please Contact Us if you need a size we do not currently show on the site, or if you would like to design your own color layups.

Custom color and size orders are subject to minimum order requirements and may require longer turnaround time than our standard product set. A deposit may be required for custom orders, the deposit is non-refundable after manufacturing commences.

Understanding New USPS Package Size Surcharges

From April 3rd 2022, the Post Office is introducing additional shipping charges for larger packages. If a package is 22" long, USPS adds $4 to the shipping cost. If the package is 30" or more, the surcharge is $15. If the total volume of the package is 2 cubic feet or more, USPS adds an additional $15 to the shipping cost.

This means that a shipment may cost up to $30 more to ship than before the surcharges came into effect

Important note: This level affects only the longest and heaviest shipments, and there is usually a cheaper alternative shipping method from UPS

We have taken steps to ensure that you are shown the true cost of shipping, including surcharges when you make your selection of shipper and service level. However to do this we have had to create a program that estimates the size of the shipping box or package. Due to the complexity of this, we can not guarantee that it is 100% accurate every time.

If the cost of shipping is significantly higher than the shipping fee charged at checkout, we will first check to see if there is a cheaper alternative with approximately the same delivery time, and use that service instead. If in doing so we can save you money on shipping, we will refund you the difference after p&p costs.

If no alternative is available, we will contact you to discuss options - for example to see if it is possible to cut longer pieces down.

Reviews

Dan - California, USAA great blank, well packaged and fast shipping

Jeff Harrison - Maryland, USAWow!!

This stuff turns nice! [Frogwood® RHD5]

Much more smooth than rutland, and definitely more "wood like" than dymalux...

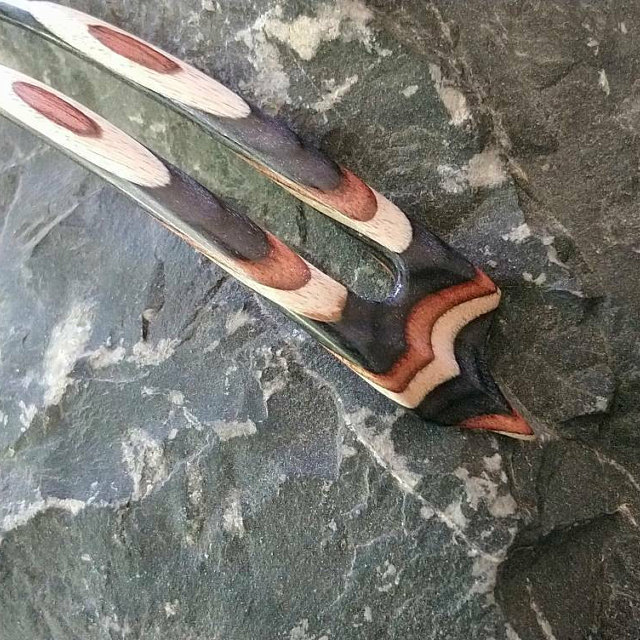

It grips very well on all the playing surfaces (slate, glass, aluminum and titanium.) The sound is very good, and lively....does not have the dull plastic tone to it that others have.

Mara - Rostock, GermanyNice material: easy to polish, high gloss finish, slightly flexible - better than SpectraPly® and lighter than stabilized alternatives :)

Mara creates hair forks "haarforken" in a variety of woods and other materials

Sköldpadda Haarforken

Lynne - Auckland NZI found working with FrogBlanks on the lathe very satisfying. No tear-out, as sometimes happens with laminated wood (e.g. when working with skateboard decks). Can't wait to turn more, and apply them to other projects.

Lynne creates beautiful rings & other jewelry in a variety of materials

YouWoodNz - Handmade in New Zealand

Mick- Cincinnati, OHCool and unique wood, easy to work with will buy again, thanks!

Check out Mick's spectacular selection of knives

Mhagmx Store

DeanUsed this blank on a gunmetal/gold Devin click pen. Giving this as a gift to a WVa State Trooper at my church. Thank you for a quality product and fast shipping!

Dean's Etsy shop will be opening soon

We'll post a link as soon as we have it!

Working with Frogwood®

Machining Frogwood

Use very sharp cutting tools, carbide if possible. Medium spindle speed for turning with low to medium feed rate for roughing. High spindle speed low feed rate for finishing. Consider this material like cutting cherry not soft like pine or hard like ash. The material is birch which has been bonded together with an adhesive under pressure which tends to make it slightly harder.

Finishing Frogwood

Frogwood is made from birch, a reasonably open-grained material. This takes well to all types of shellacs, Polyurethanes and other surface finishes. This material can also be finished with CA glue finish if desired. In our experience when producing finished products using this material, many customers preferred a simple high polish waxed finish.

Privacy Policy for Streamers LLC

At FrogBlanks, accessible from FrogBlanks.com, one of our main priorities is the privacy of our visitors. This Privacy Policy document contains types of information that is collected and recorded by FrogBlanks and how we use it.

If you have additional questions or require more information about our Privacy Policy, do not hesitate to contact us through email at [email protected]

Log Files

FrogBlanks follows a standard procedure of using log files. These files log visitors when they visit websites. All hosting companies do this and a part of hosting services' analytics. The information collected by log files include internet protocol (IP) addresses, browser type, Internet Service Provider (ISP), date and time stamp, referring/exit pages, and possibly the number of clicks. These are not linked to any information that is personally identifiable. The purpose of the information is for analyzing trends, administering the site, tracking users' movement on the website, and gathering demographic information.

Cookies and Web Beacons

Like any other website, FrogBlanks uses 'cookies'. These cookies are used to store information including visitors' preferences, and the pages on the website that the visitor accessed or visited. The information is used to optimize the users' experience by customizing our web page content based on visitors' browser type and/or other information.

Privacy Policies

You may consult this list to find the Privacy Policy for each of the advertising partners of FrogBlanks. Our Privacy Policy was created with the help of the Privacy Policy Generator.

Third-party ad servers or ad networks uses technologies like cookies, JavaScript, or Web Beacons that are used in their respective advertisements and links that appear on FrogBlanks, which are sent directly to users' browser. They automatically receive your IP address when this occurs. These technologies are used to measure the effectiveness of their advertising campaigns and/or to personalize the advertising content that you see on websites that you visit.

Note that FrogBlanks has no access to or control over these cookies that are used by third-party advertisers.

Third Party Privacy Policies

FrogBlanks's Privacy Policy does not apply to other advertisers or websites. Thus, we are advising you to consult the respective Privacy Policies of these third-party ad servers for more detailed information. It may include their practices and instructions about how to opt-out of certain options. You may find a complete list of these Privacy Policies and their links here: Privacy Policy Links.

You can choose to disable cookies through your individual browser options. To know more detailed information about cookie management with specific web browsers, it can be found at the browsers' respective websites. What Are Cookies?

Children's Information

Another part of our priority is adding protection for children while using the internet. We encourage parents and guardians to observe, participate in, and/or monitor and guide their online activity.

FrogBlanks does not knowingly collect any Personal Identifiable Information from children under the age of 13. If you think that your child provided this kind of information on our website, we strongly encourage you to contact us immediately and we will promptly remove such information from our records.

Online Privacy Policy Only

This Privacy Policy applies only to our online activities and is valid for visitors to our website with regards to the information that they shared and/or collect in FrogBlanks. This policy is not applicable to any information collected offline or via channels other than this website.

Consent

By using our website, you hereby consent to our Privacy Policy and agree to its Terms and Conditions.

Limited Warranty

- In the event of a manufacturing defect, we will replace or refund the defective product. We may request that you return the part for analysis, in which case we will pay for return shipping

- We aim to provide pieces that are at least the dimensions stated, but due to normal manufacturing tolerances we can only guarantee +/- 1/16th inch

- Colors vary with lighting conditions; we photograph all pieces either in sunlight or natural-light balanced fluorescent lighting. However, computer screens vary from device to device, and also change as they age. We can not guarantee that the colors that you see on the screen are an exact match to the colors of the material

- Always wear protective clothing and eye protection when turning any material